Future logistics

This is the result of a student project and does not necessarily represent the views of the brand.

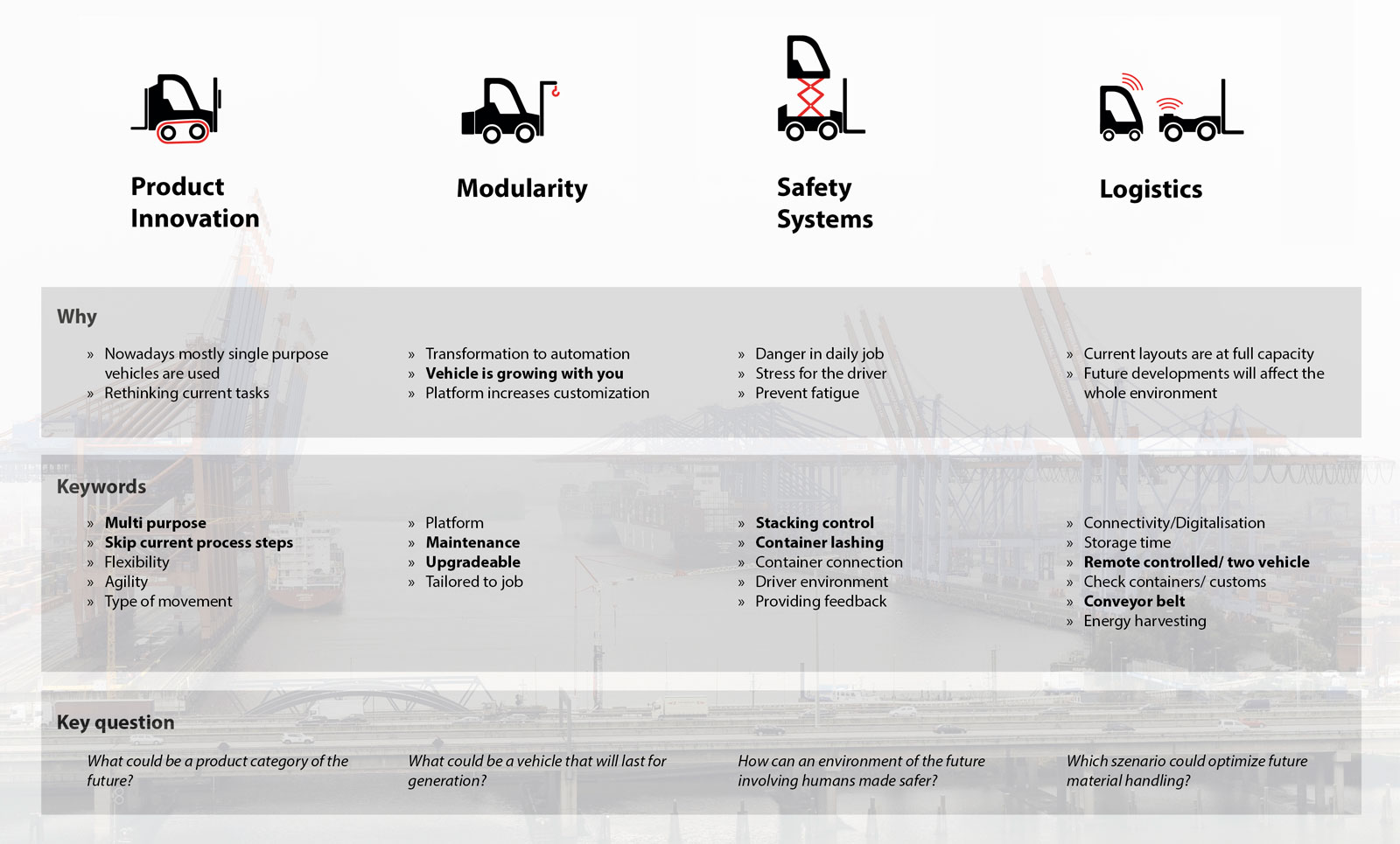

Currently there are about 800.000.000 containers in use all over the world, transporting goods on vessels, trains or trucks and numbers are steadily increasing. To maintain a high level of efficiency and enable a constant throughput, logistic companies are facing major difficulties to keep up with the increasing pace. Kalmar supports industries worldwide when it comes to material handling, providing heavy duty material-handling equipment for several industry branches with a focus on the port area. With current trends such as automation, digitalization and sustainability they were looking for solutions for their coming generations of material handling equipment.

Currently there are about 800.000.000 containers in use all over the world, transporting goods on vessels, trains or trucks and numbers are steadily increasing. To maintain a high level of efficiency and enable a constant throughput, logistic companies are facing major difficulties to keep up with the increasing pace. Kalmar supports industries worldwide when it comes to material handling, providing heavy duty material-handling equipment for several industry branches with a focus on the port area. With current trends such as automation, digitalization and sustainability they were looking for solutions for their coming generations of material handling equipment.

„How can a next generation autonomous vehicle increase efficiency in a limited space?“

Research

In order to get in touch with the vehicles as well as to gather hands on insights from professionals using the machines, we went on a research trip to Kalmars main production site in Poland, the harbor city of Hamburg where we got the chance to see the complete process of container handling and a small saw mill site in Vännäs just outside of Umeå. During the research three main difficulties stood out:

Storage Higher demands, growing cities and bigger vessels are asking for increasing capacity while companies are already working on their full capacity which is usually limited by either space itself or regulations limiting the usage of it.

Time.. is money and so is the throughput of goods. Every container that needs to be stored means it blocks the space of a new one to come. Reducing storage time is always the aim but also downtime is a present risk.

Organisation The biggest influence is the process organization itself. This means surveilling e.g. information of arriving and departing transport, maintenance, working hours and unexpected occurrences.

Storage Higher demands, growing cities and bigger vessels are asking for increasing capacity while companies are already working on their full capacity which is usually limited by either space itself or regulations limiting the usage of it.

Time.. is money and so is the throughput of goods. Every container that needs to be stored means it blocks the space of a new one to come. Reducing storage time is always the aim but also downtime is a present risk.

Organisation The biggest influence is the process organization itself. This means surveilling e.g. information of arriving and departing transport, maintenance, working hours and unexpected occurrences.

Straddle Carriers

During the onsite research one of the vehicles stood out. The straddle carrier is used in both midsize and large ports to transport full containers from the vessel into the storage or directly on to trucks. Ever since their introduction not much has changed in form or their construction. Through their immense height they are able to stack up to 4 containers but the next generation of straddle carriers are faced by even higher needs of capacities and efficiency.Analysis

Transferring containers between vehicles is one of the most time consuming task, followed by moving the containers itself inside the port layout and inside the stock. Calculating the estimated time savings for different port types proofed the value of an enhanced straddle carrier concept which is suitable for small and big ports, being more versatile than current solutions and reducing transferring steps.

Requirements

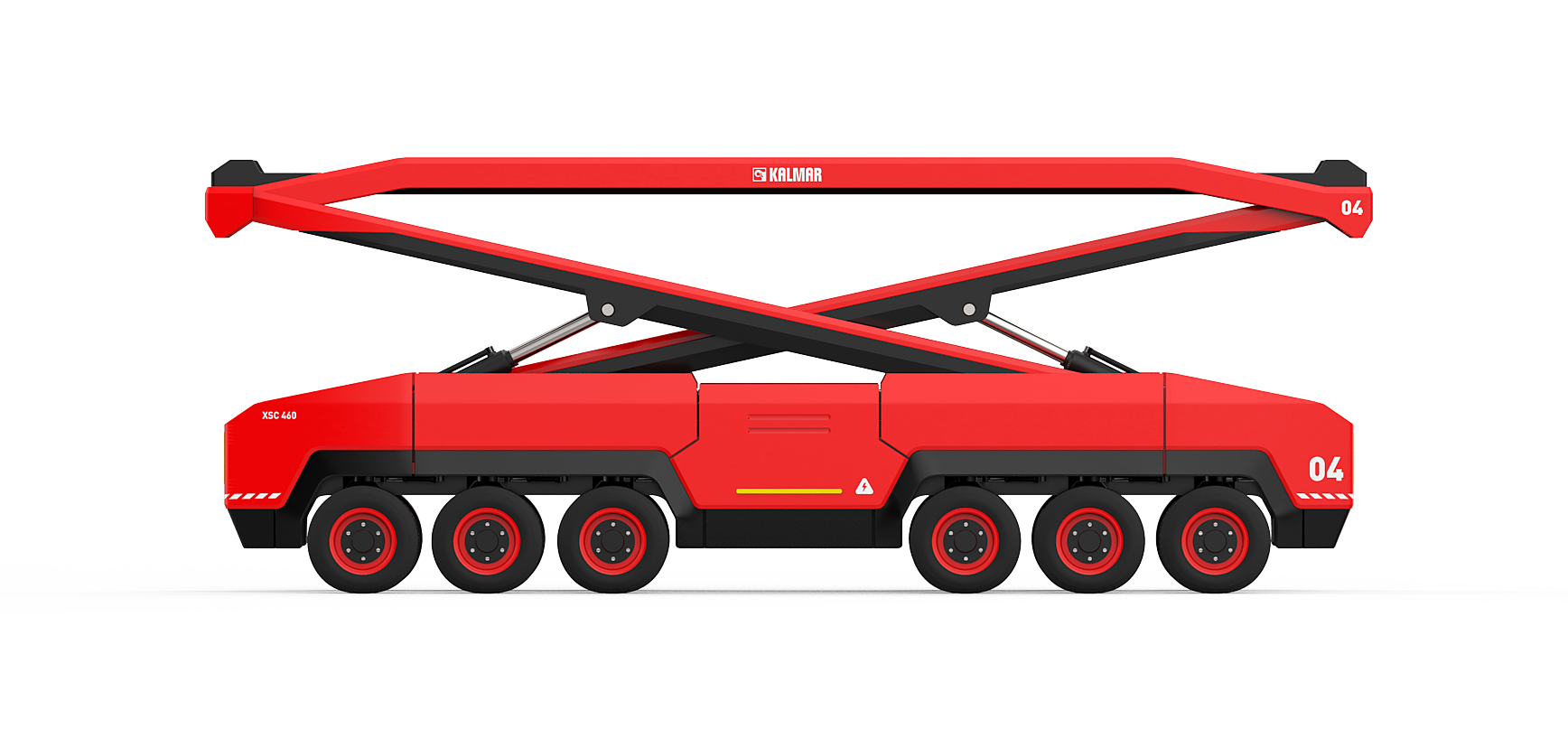

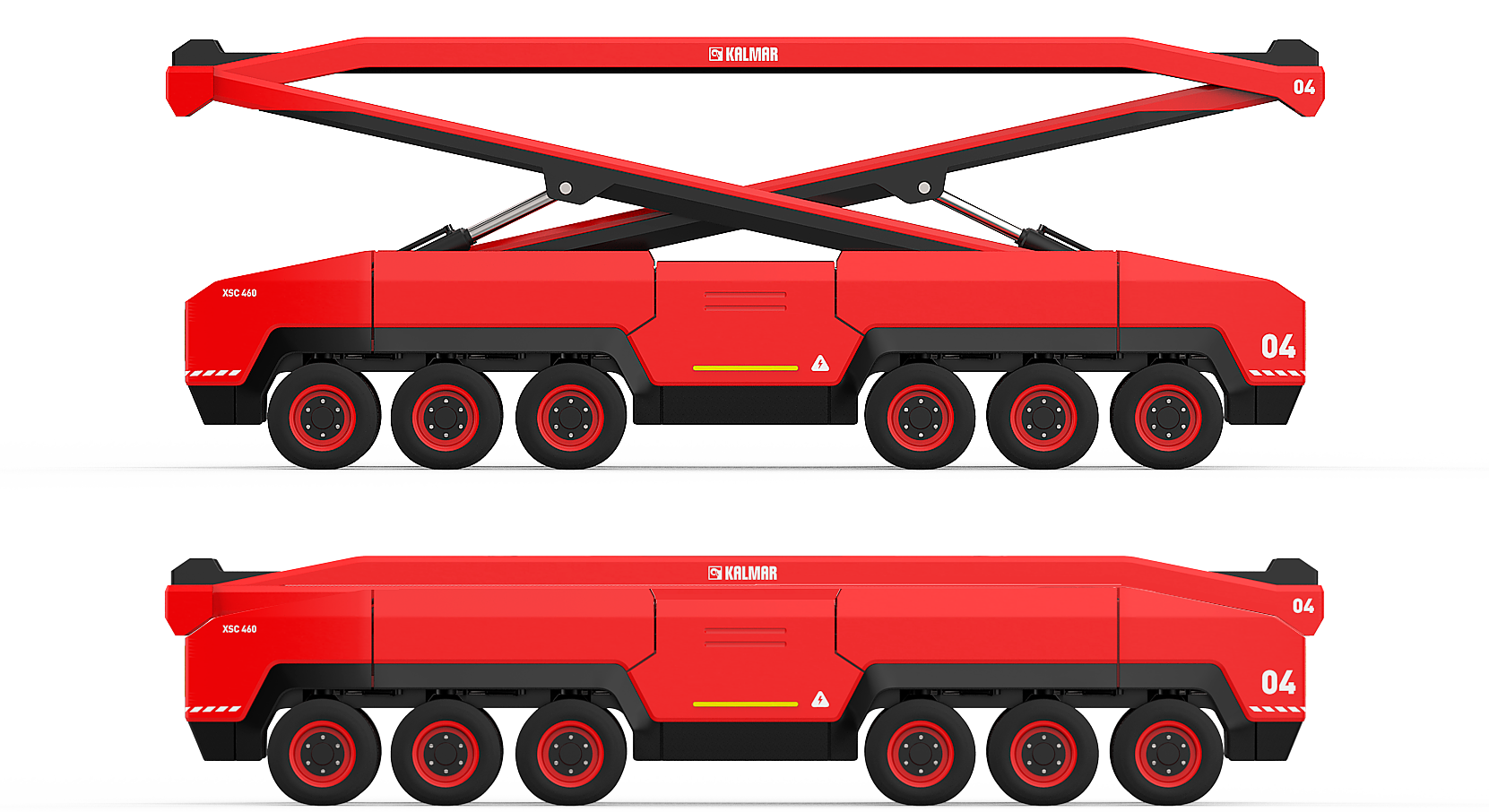

After the analysis certain requirements for the next generation straddle carrier were set. To increase the efficiency there will be the need to carry two containers at once but also to pick up and unload itself independently. Because nowadays the port areas are more and more limited a future vehicle should also provide the possibility to interact with the whole port environment hence must be street legal.

Concept

After the initial research it became clear that to take a step further the concept of a lifting vehicle needs to be rethought. Lego technics helped to sketch out and validate basic ideas. In order to pick two containers at once, they are locked from the sides instead from the top. To move in between the container lanes a connection of the wheelbases isn't possible, therefore the only connection is provided via the arms and frame.Contruction

The vehicle consists of two separate wheelbases on which on each of them two hydraulic powered arms are lifting the container. This concept allows for a minimal height and improved stability while transporting longer distances. The full height is only needed inside container isles where only a slow movement are necessary and which provide a shelter from strong winds.

Lifting

Two containers can be lifted at the same time, increasing the efficiency to a new level. Locks on the outer corners but also in der middle allow the lifting of 20 and 40 feet containers.

Distance measurement

To ensure the wheelbases are moving in a straight direction the distance between them is constantly measured and compared between the front and back.Wheels

Twelve wheels allow for a low overall height and a small turning radius through an individual steering mechanism.

Agility

The enhanced straddle carrier can be used in a variety of applications because of its low height. The batteries placed in the centre of each wheelbase are easily swappable for a non stop usage.