Designing a surgery

In cooperation with Bosch Healthcare Solutions I developed and designed a new surgical instrument and the accompanied surgical process. The project focused on user centered design, involved a detailed on-site research to grasp information on usage and requirements, creating and evaluating ergonomically studies, developing feasible mechanical solutions as well as creating and incorporating design guidelines. Because of the new technology being used not only the instrument itself but the whole process was rethought from start to finish. The result was achieved in close cooperation with medical professionals as well as engineers of Bosch. Because of pending patents, the final result can't be shown at this moment.

„How does a surgeons' dream instrument look like?“

![]() Intuitive

Intuitive

The most prominent requirement has been the intuitive handling of the instrument allowing for a blind usage.

![]() Precise

Precise

A surgical instrument needs to live up to the surgeons abilities and provide the highest level of precise handling.

![]() Ergonomic

Ergonomic

Using and setting up the instrument needs to be simple and comfortable to allow for a flawless process.

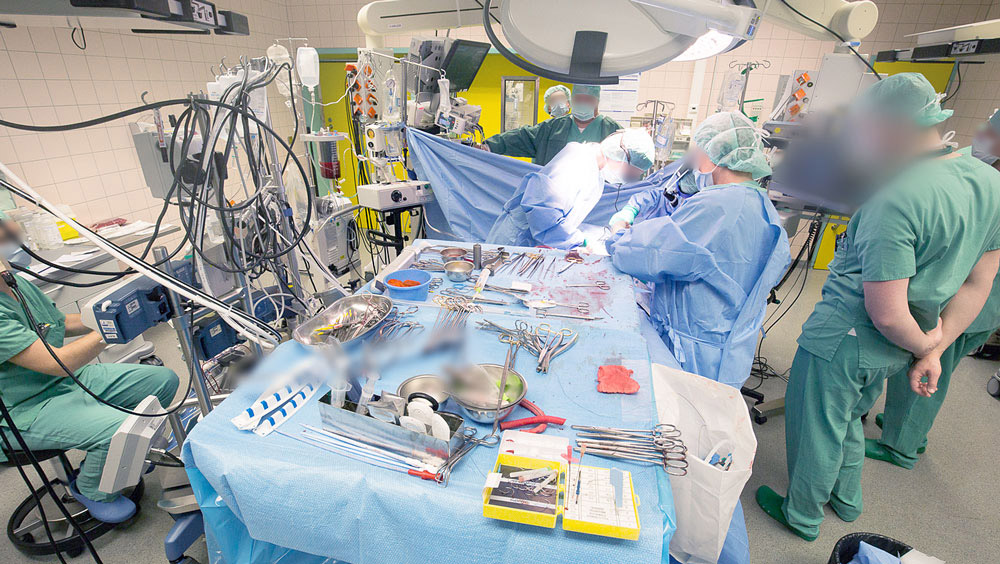

On site analysis

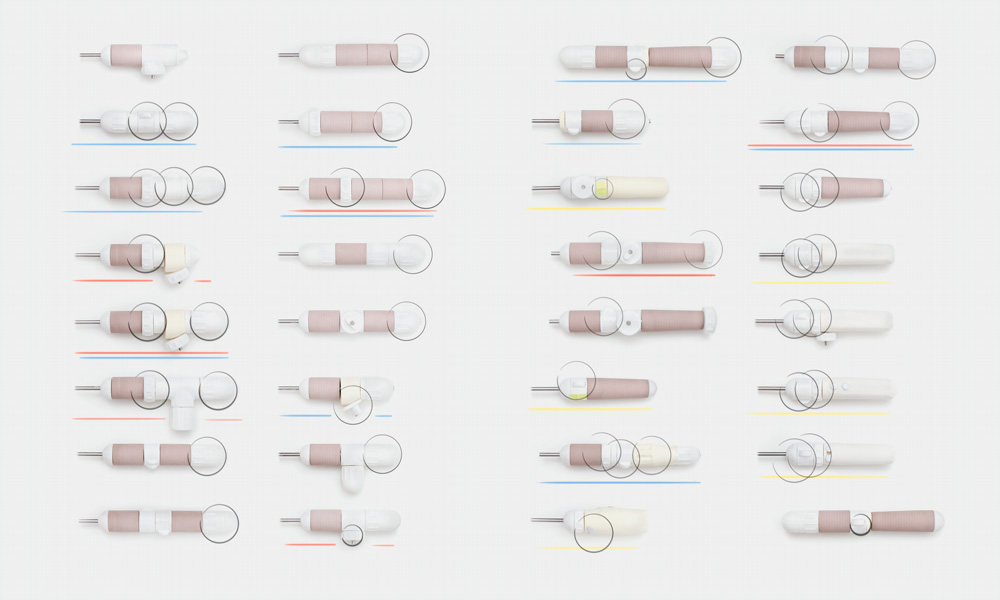

Being on site allowed for a detailed problem analysis and the definition of requirements.Early prototyping

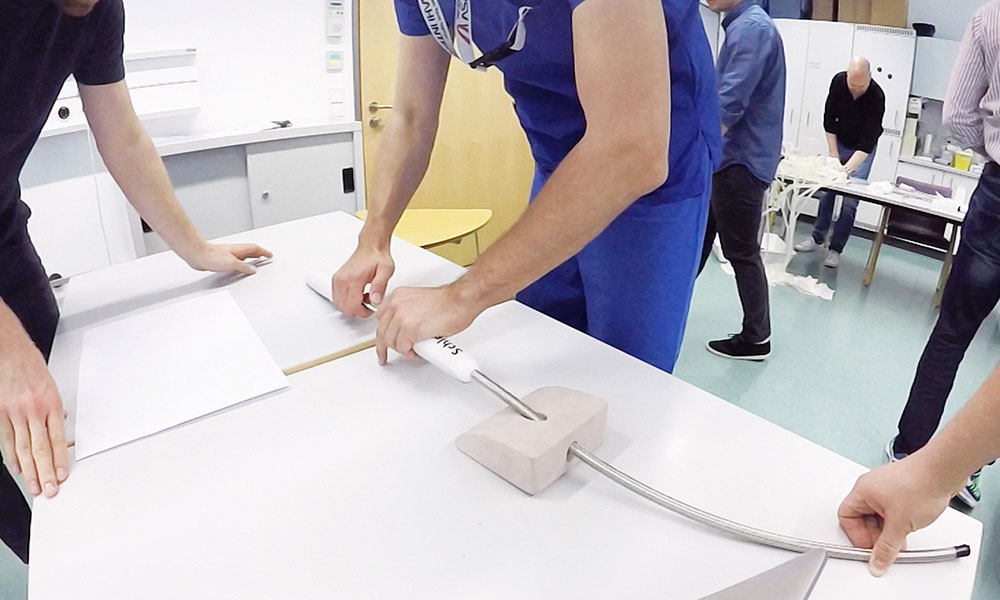

A modular system of handles and functional elements made a quick and easy evaluation of the optimal structure and measurements possible.

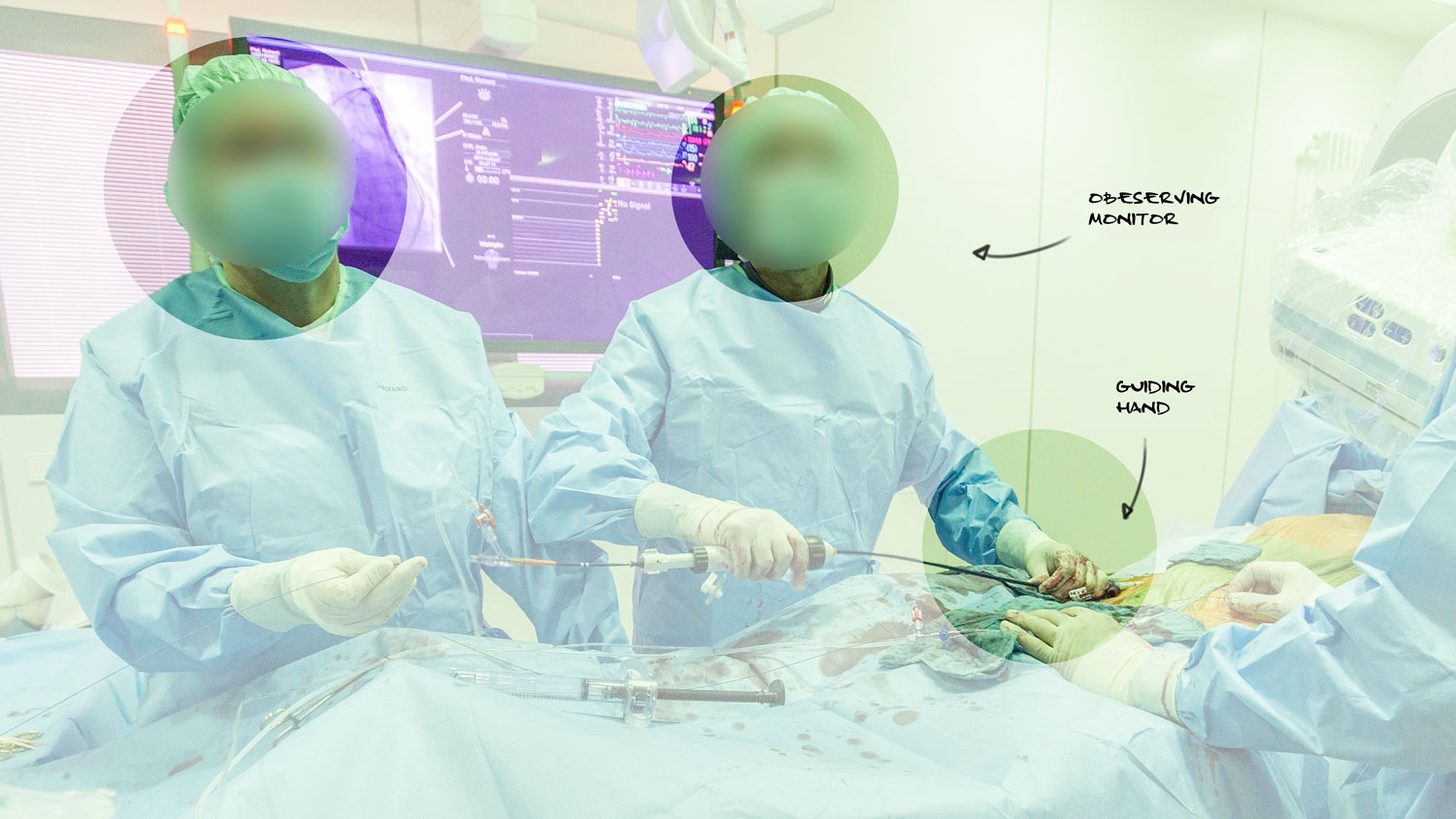

Ergonomic validation

Based on the modular system ergonomics, intuitive handling and the set requirements were analyzed.User testing

Using 3D printing, first prototypes with basic functionality were made and used in user tests with different personnel.

„How can design help optimising the

process of a surgery?“

![]() Preparation

Preparation

Before the actual operation the operating room needs to be set up. An optimized process shortens the preparation time.

![]() Team work

Team work

The positive outcome of a surgery is much influences by the quality of teamwork. Supporting communication and easy interaction between the participants is crucial.

![]() Packaging

Packaging

Space inside an OR is very limited, handling packaging can be a full time job. A smart packaging solution makes handling and keeping record of used equipment easier.

![]() Process

Process

During a complex surgery a lot of equipment is in use and steps need to be taken in a very strict manner. Creating an intuitive workflow and obvious choices helps to simplify the process.

![]() Hygiene

Hygiene

Both objects and participants need to be sterile during the surgery which adds an extra level of complexity.

![]() Follow up

Follow up

The surgery itself won't end with the patient leaving the operating room. Taking care of used equipment as well as the aftercare of the patient adds specific demands to process.

Surgery Process

Breaking down the surgery process to make it easy to understand and discuss about has been the starting point of the project.Simulated use test

Simulated use tests with medical professionals were made in order to evaluate the designed surgery process.

Patents pending

Intuitive

Intuitive Precise

Precise Ergonomic

Ergonomic